Faster, safer and sustainable spot welding equipment

Faster, safer and sustainable spot welding equipment

Faster, safer and sustainable spot welding equipment

Ewellix has a long-standing tradition of technical expertise. We support customers in improving automotive manufacturing equipment that runs faster, longer, and safer sustainably.

Power density

Compact and robust design offering high force in small spaces

Greater productivity

High-performance technology that guarantees continuous use and flexibility

Environmentally friendly

Electromechanical solutions for noise and energy reduction

Lower maintenance

High reliability for long service life with millions of cycles

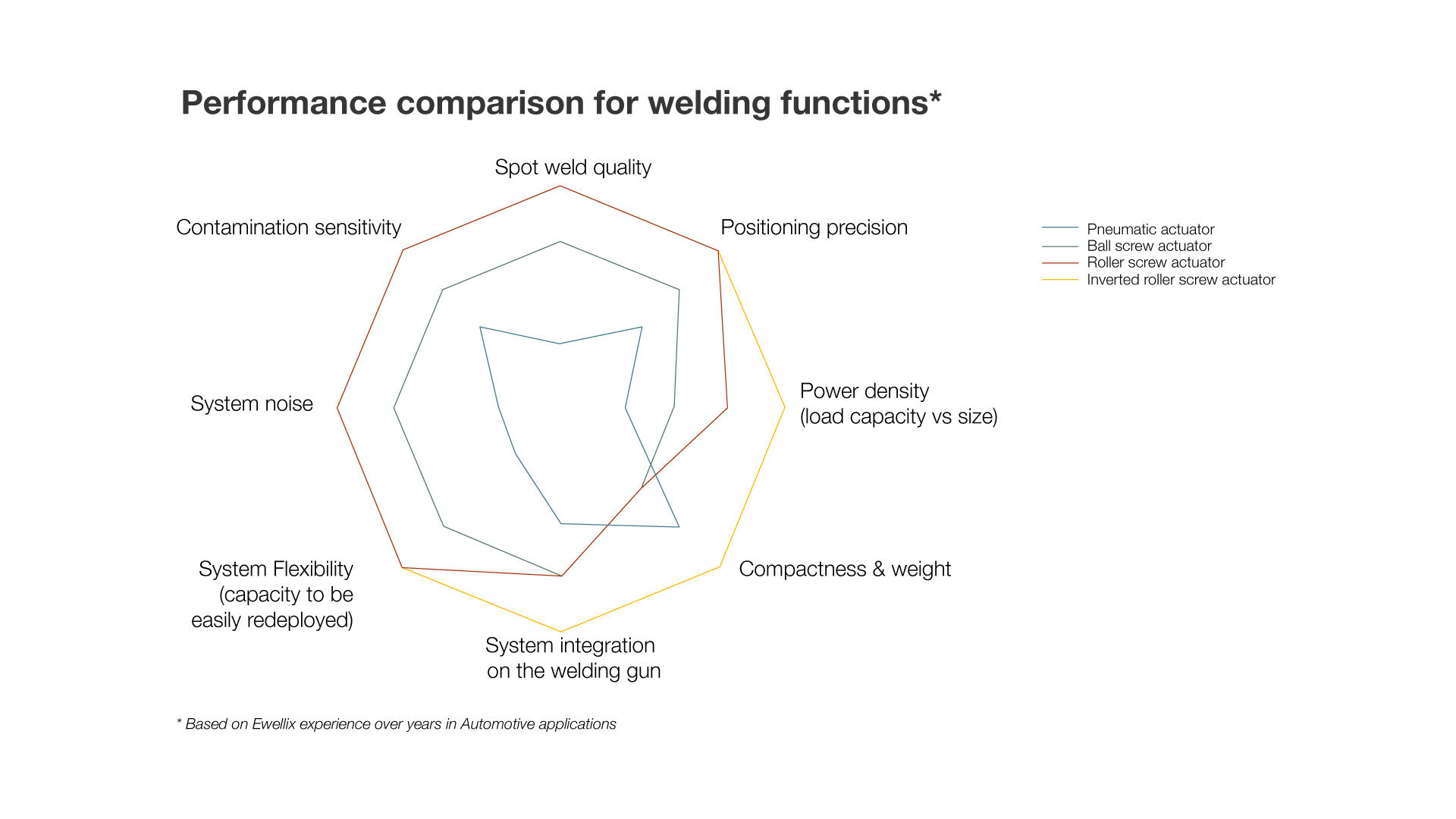

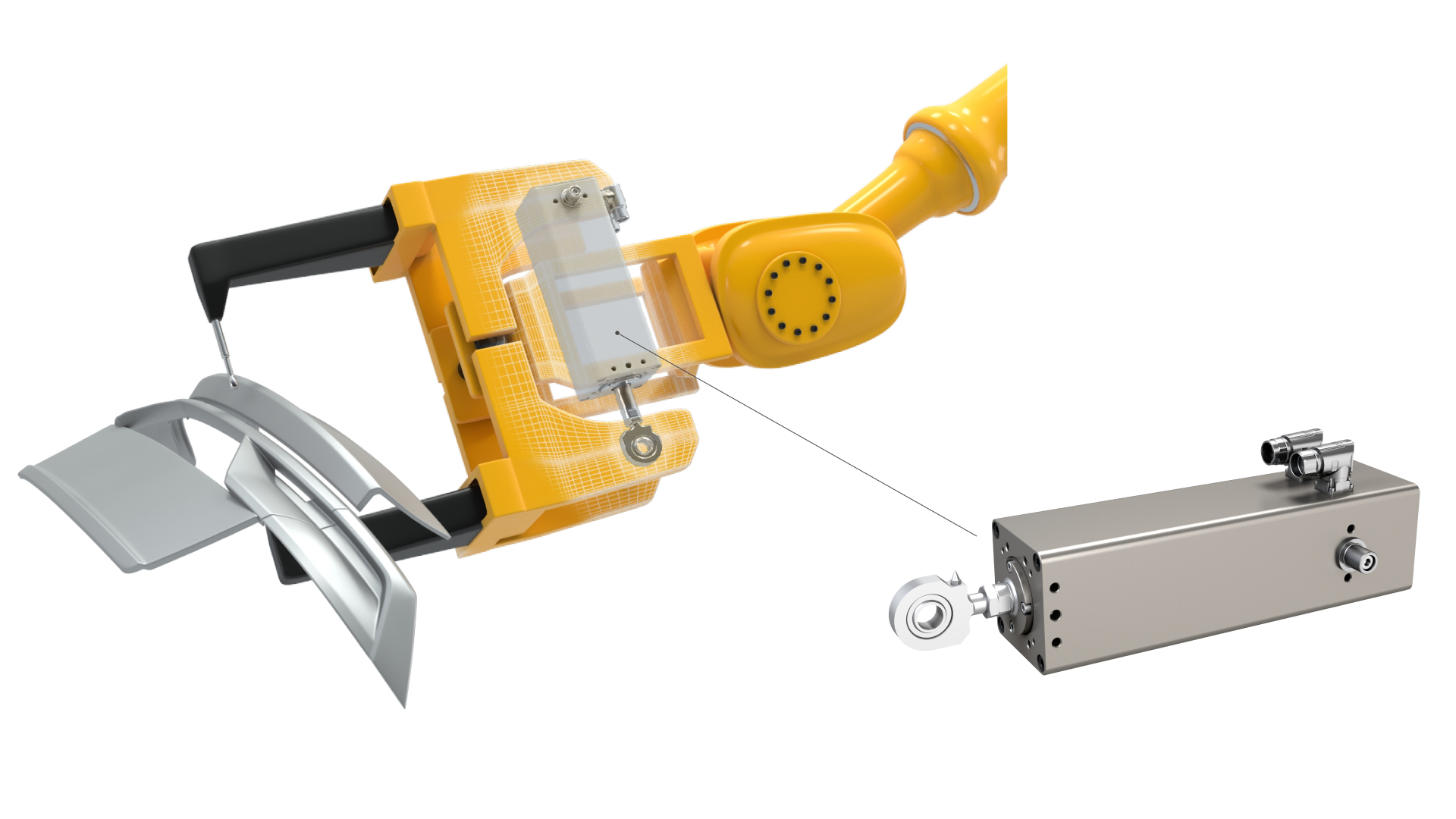

Electrical systems in automated lines help to enhance assembly processes by being flexible and programmable. Electromechanical actuators are more reliable and energy efficient than the old-style pneumatic versions. Ewellix mechatronic solutions integrated into assembly lines offer:

- Minimal maintenance

- Reduced downtime

- Improved total cost of ownership

Ewellix’s extensive product knowledge and engineering expertise transform customers’ needs into tailored solutions that focus on specific client requests.

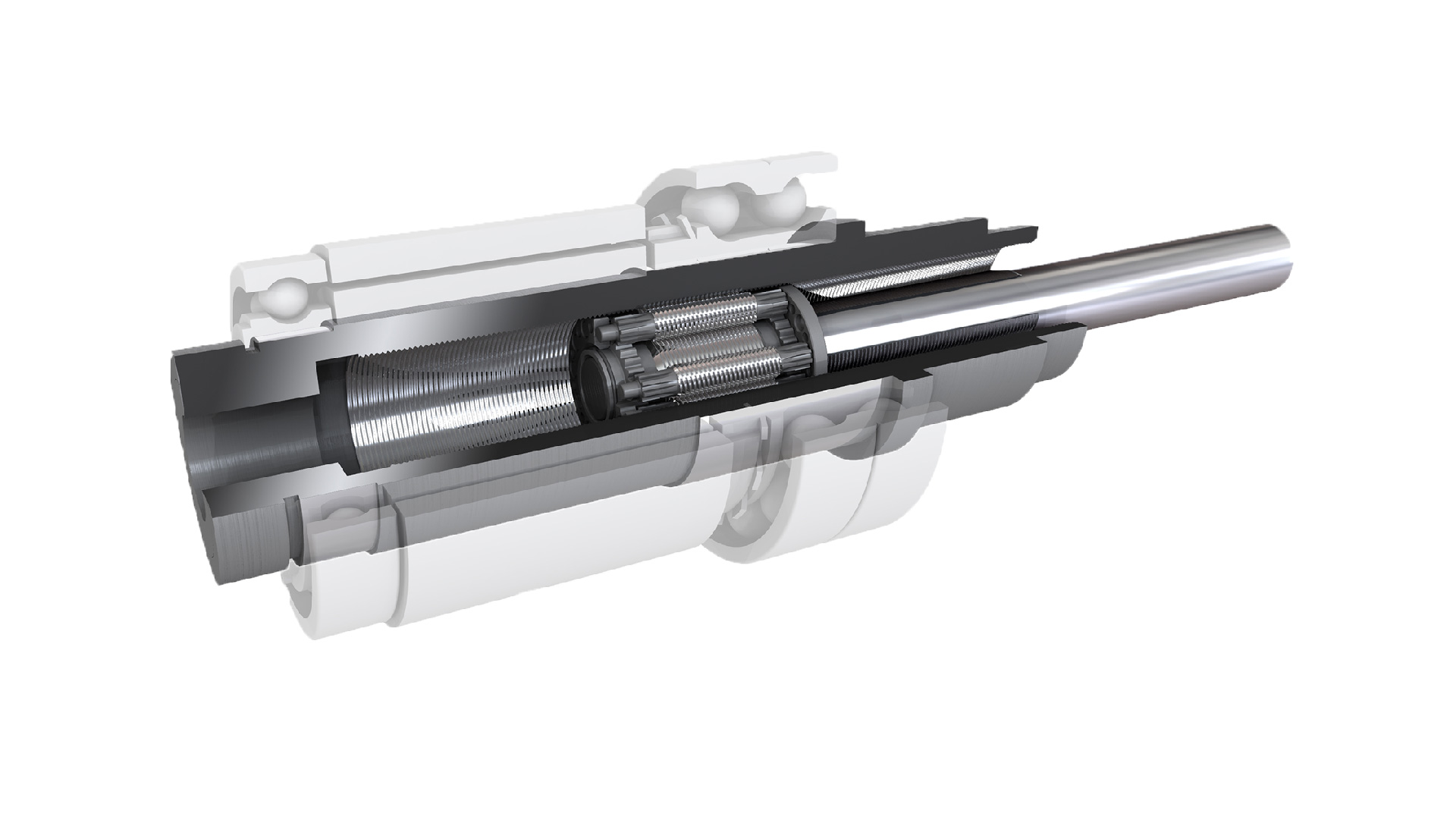

Ewellix’s core technology for automation assembly

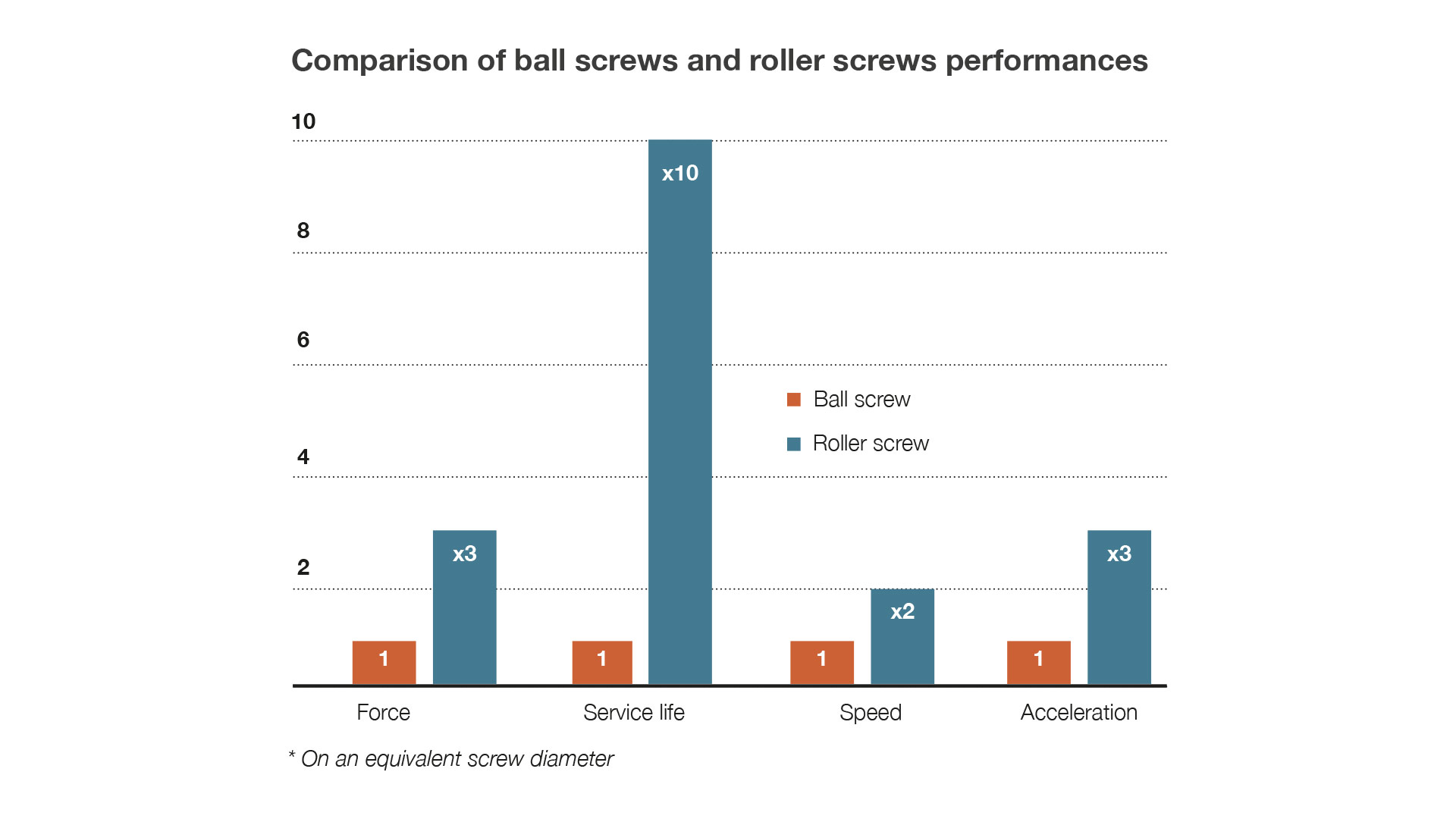

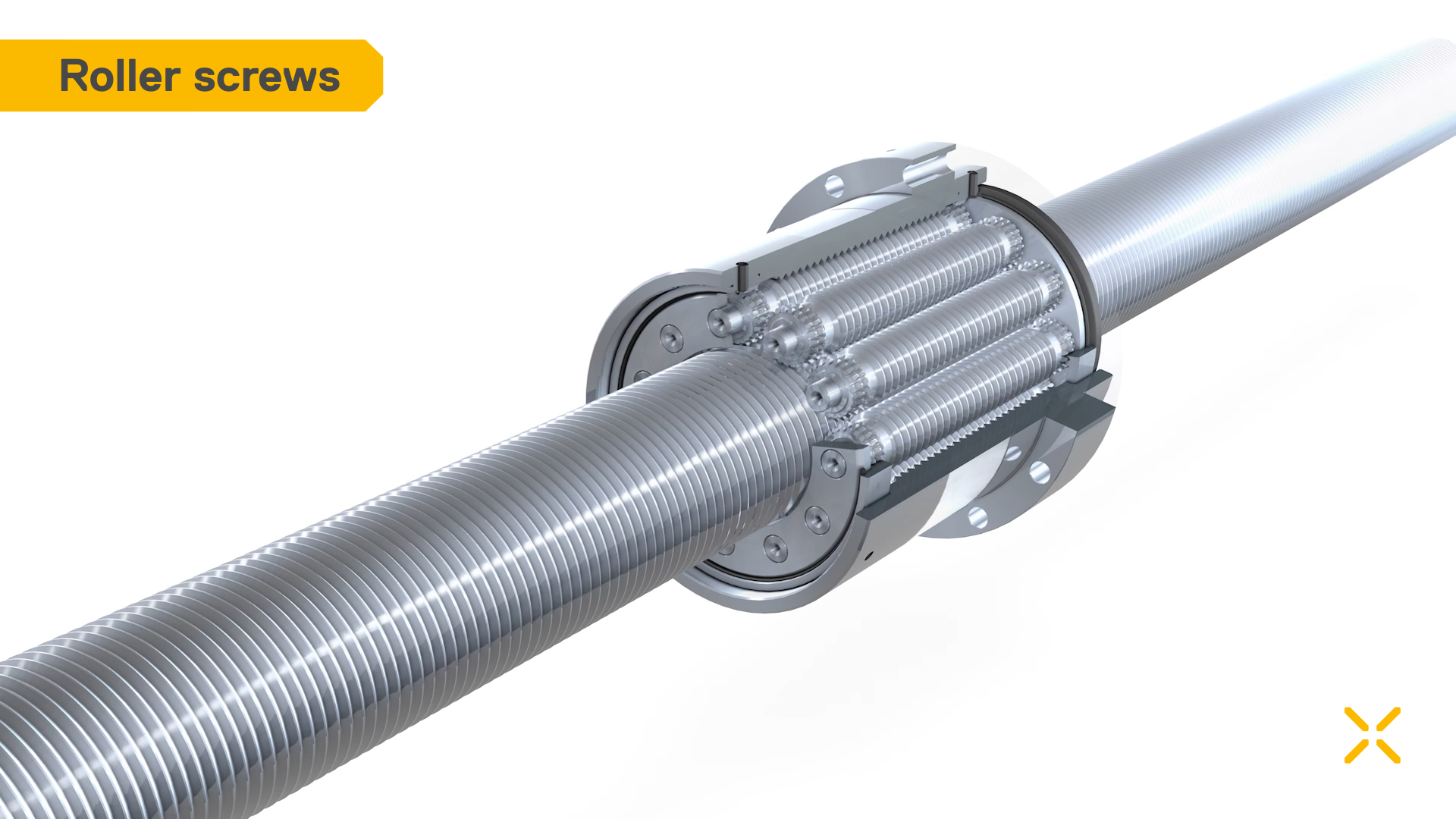

Comparison of ball screws versus roller screws performance

With a wide range of high-quality, advanced performing roller screws, Ewellix is a pioneer in this technology

Discover our solutions

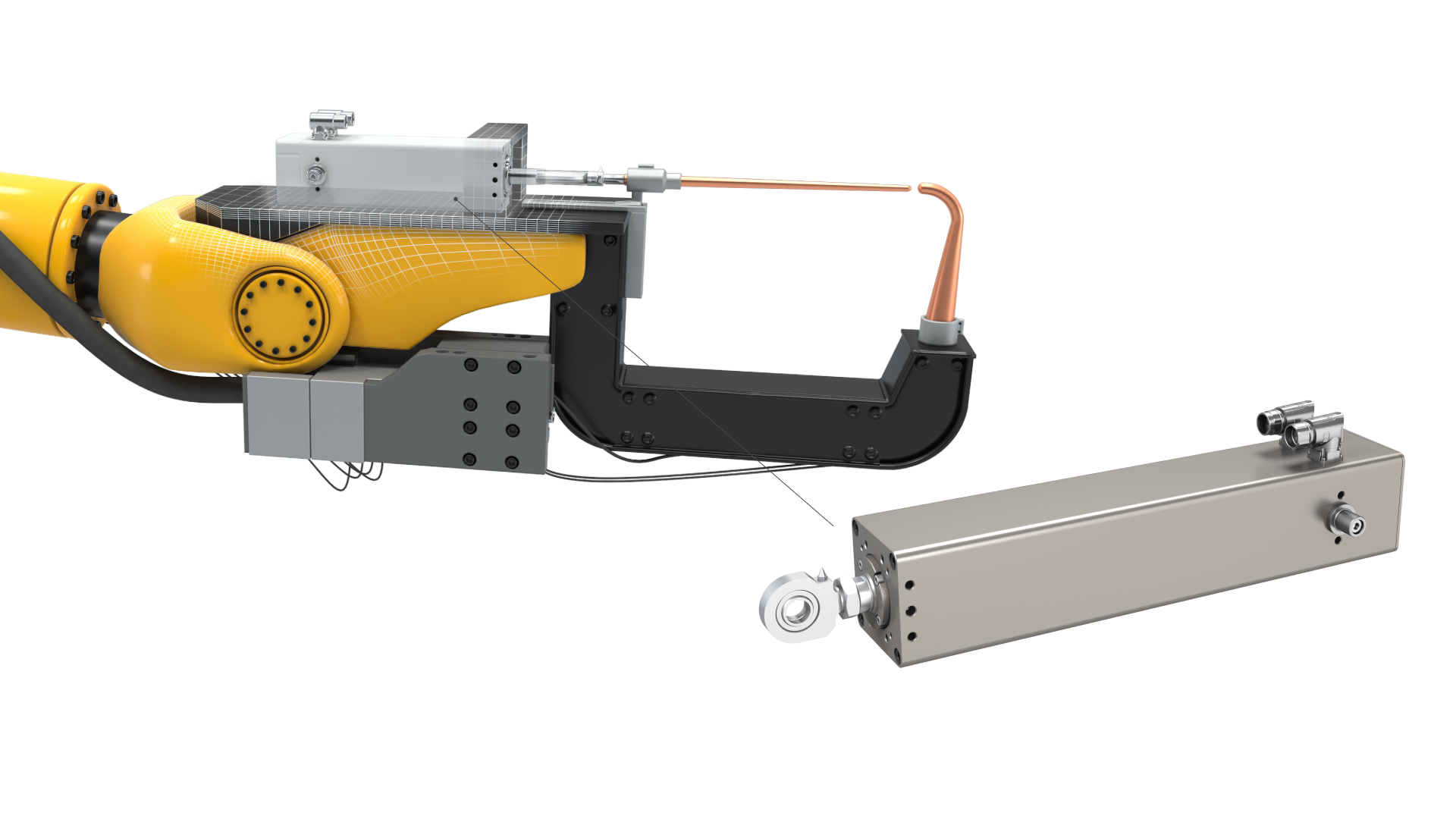

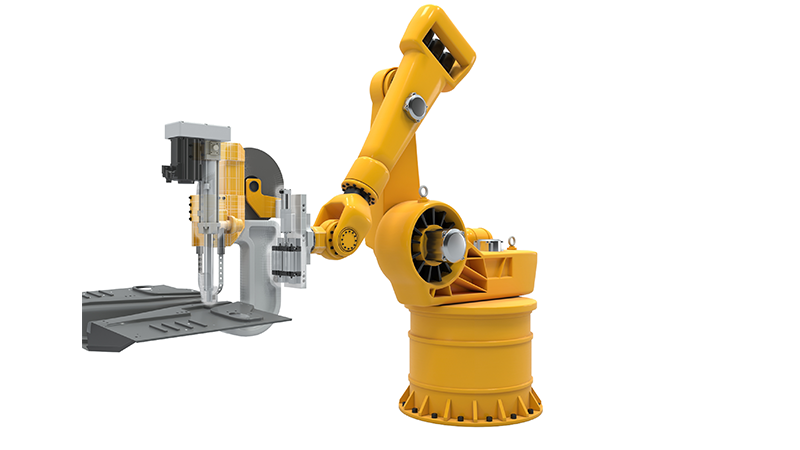

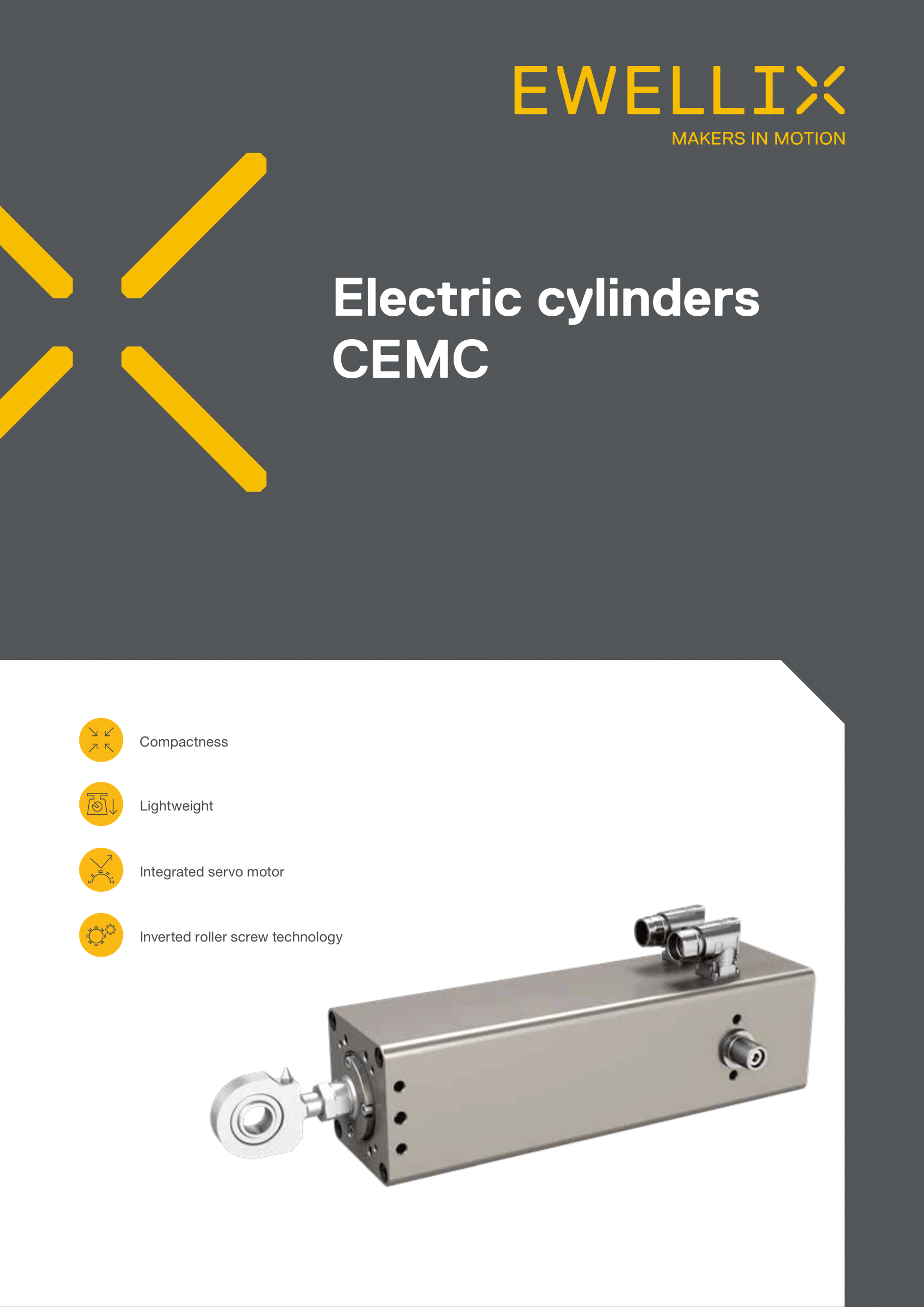

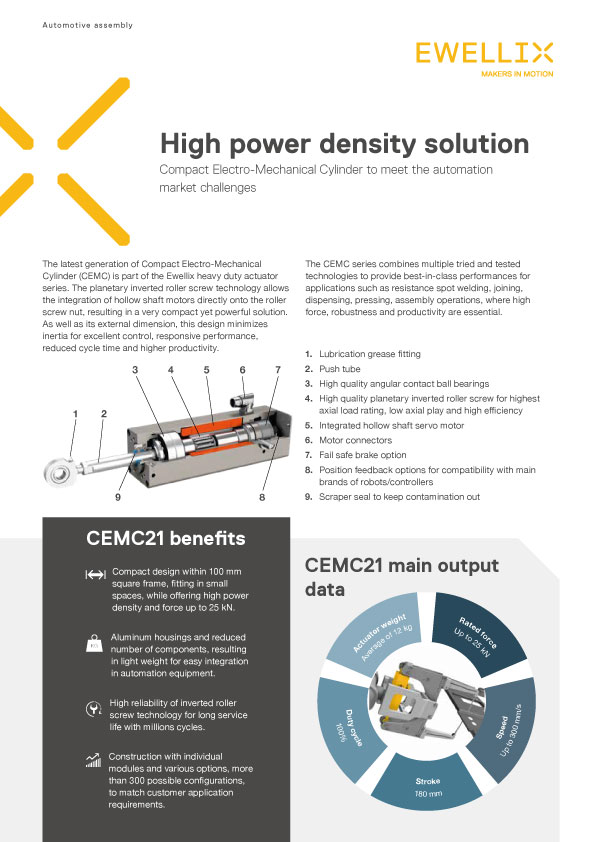

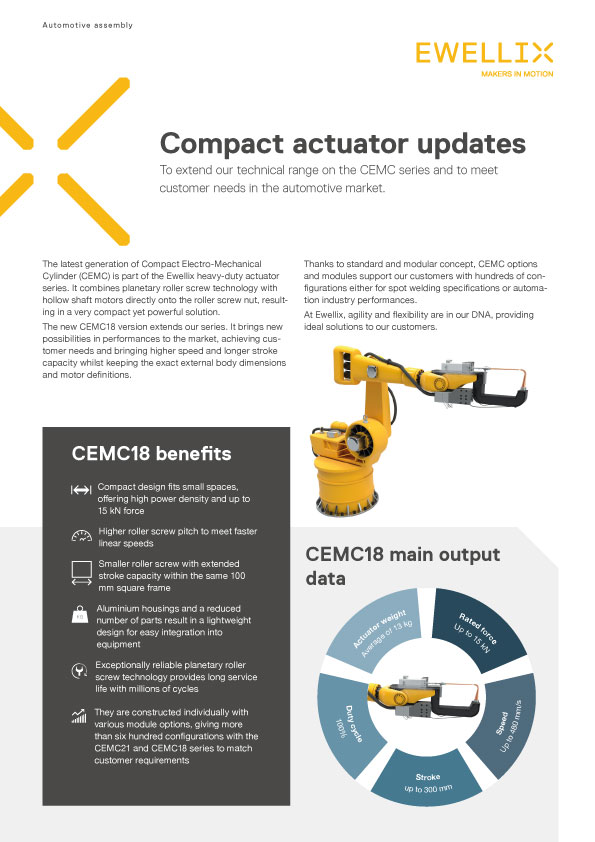

The latest Compact Electro-Mechanical Cylinder (CEMC) series provide best-in-class performances when high force, robustness and productivity are essential. The planetary inverted roller screw technology allows the integration of hollow shaft motor offering numerous advantages for welding that requires high load, very long service life and extreme reliability.

Smart CEMC

The resistance spot welding process is an established method that has been used for decades in the automotive sector. New materials, however (like aluminium or high tensile steel), are changing and pushing the process to the limits. Accurate measurement of the welding force during the process is essential to ensure the quality of the joints.

Products

Applications

Publications

Video

Do you have any questions?

Contact our experts.

Please complete the form with your contact details and briefly explain your request. We will contact you as soon as possible.